Lot of things coming together these past weeks. Silver Creak Auto Body has been moving right along on the cab while we have been making process on the frame.

Inside the cab has been sprayed with a sound deader paint.

Finishing up on the last of the sanding before paint.

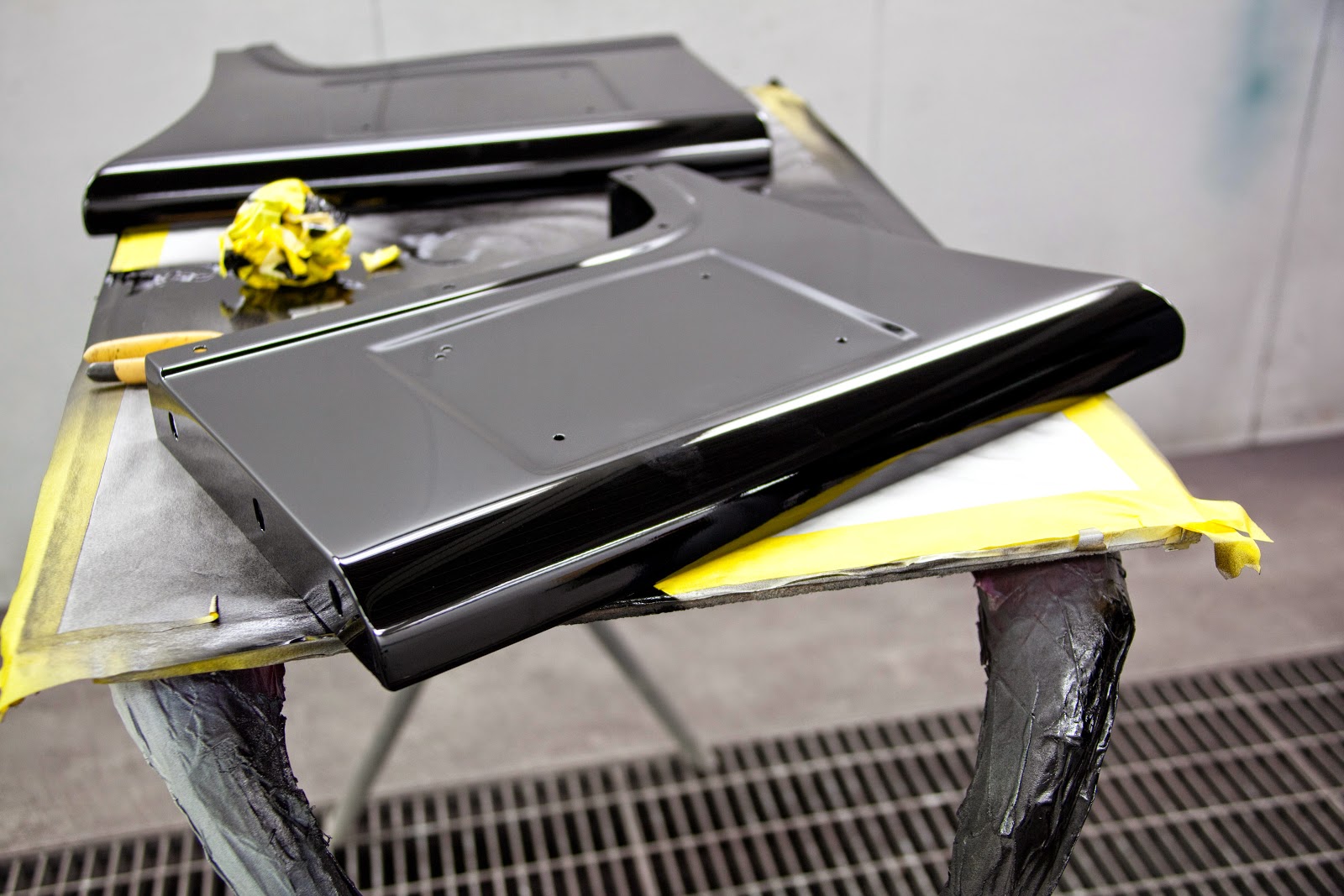

Under the hood and some small parts with final paint. Pinch me I think I'm dreaming.

The lower part of the truck box is almost finished and we where able to get measurements for water, waste, and gas tank. BBC is forming up the boxes and Chris will weld them and finish them up. Plan is to try and get most of the prewiring and plumbing done before we lay the floor.

Literately pick up the generator today. Went with a 7000 Cummins Onan with 58 amps. Will be using about 80 percent of its capable power.

The new home for the generator.

Bracket that was fab to hold the generator.

All mounted in and ready to be plumbed in.

First gas tank fuel pump installed. Running with a EZ Fast fuel injection set up with a 3/8" feed and a 1/4" return.

Also ran brake lines and a fuel line to the generator.

Ran all hard lines and used soft to terminate at the ends.

Next week we will finish up the 3/16" lines to the calipers and lines from the master cylinder to the proportion valve. Its amazing how much time it takes to plan and route the lines. You keep asking your self if I ever have to replace this part will I be able to get to it or is it to close to a heat source or will it get damage by something it comes in contact with. With that being said thing are moving forward and looking awesome.