Not a lot of exciting things happening on the truck so far this summer. Well I should say not exciting in the fabrication aspect of the project anyway. We have been working on all the loose end stuff to get it ready for the trip to the body shop. The final piece of the exterior is to finish up the service window. We have the door opening tact in and will have to wait till the box get painted to finish up the final opening. This is so we can remove the siding and get the paint under the lip that the siding butts up to. The interior of the box will also wait till after paint so that the panel could be body worked from both sides. Been working on the logo that will be on the side of the polished portion of the box. It will be about 25"x 84" when done and be machined out of aluminium. Chris finished up the brackets for the propane tanks and the siding to complete the back area of the truck. Chris has been working on a vintage trailer for a customer and when finished we will start to work on some of the assembly of the cab and get it ready for some of the upholstery work. We're hoping to have the box back from paint by the end of the year so we can get started on putting things together. So unfortunately you won't see many post till then. I will try and keep everyone up to date on the progress.

The first time the box has seen daylight. Getting ready to load the beast on the trailer.

It was great to see the box from a different perspective and to take it all in.

Well this was the last shot I took before we loaded it on to the trailer. I planed on taking more but I got a little stressed when loading the truck and taking pictures was now not my top priority. We had a 24' 14000lb trailer with a hydraulic tilt bed thinking we had plenty of trailer. We could have used about 3' more and things would have been a lot less stressful. We had two winches to pull the truck up on the bed of the trailer which work great till we started to lower the tilt bed down. When you see the front of the bed go down and the back is still about only two inches off the ground you start to panic a little. Of course we borrowed the trailer from a good friend and I'm thinking we are totally bending his bed frame in two. We facetime him to see if we should continue and he said keep going it will be fine. It worked, but we had no tongue weight on the trailer. After about two hours of working on getting more weight up front and making sure we where safe to make the 35 mile journey we headed out. The good news is that we stop at the scales to get a starting weight before we started, then we stop and weighed the load. The truck weigh in at 8900lbs. We took it real slow and only had one of those I should slow down feeling. We started to load the truck around 10 and where unloaded at the body shop at 5. Over all it was a good day with no unforeseen incidences and the best part the body work and paint have started.

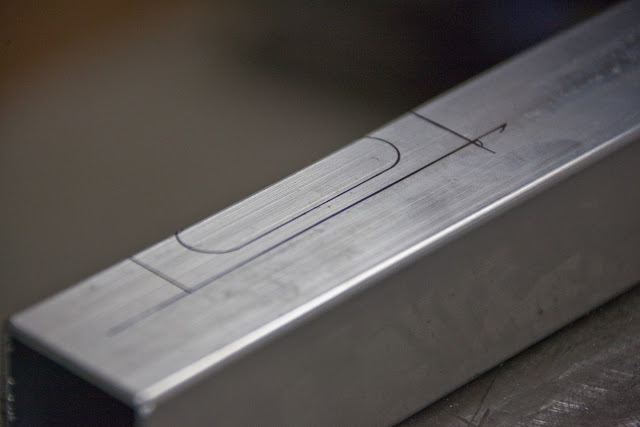

Okay maybe we have done some exciting things this summer. This is the start of the logo that was routed out of a 3/8 sheet of aluminum. Before this we had made test pieces at a smaller scale to work out any changes that needed to be made to the logo.

The guys at Meticulous Detail Manufacturing invited us over to see the project get started. It was incredible to see how the process worked to get to the finished part.

The chips were flying.

The logo will be 25" x 84" and will go on the flat polished aluminum on the box.

The chips were flying.

Chris holding up the first logo that was unfortunately not a usable part. Jesse at MDM was gracious enough to let us have the part to do some experimenting on. Some of it will be painted, sandblasted, and polished. We also made a couple of change to the part that we thought needed to be addressed for the next run. Jesse has work very hard to make this project become a reality. When things haven't been right he has made sure to make them right. If your looking for some custom work that you need done I would highly recommend the guys at MDM in Portland.

Tom over at Silvercreek Auto Body has been working hard on getting the box flat and ready for paint.

A lot of hammering and dolly work on the top panels to get it ready for the skim coat that has been put down.

Starting to work his way down the the sides.

It's coming a long nicely. Still a lot of work to be done. Sanding, blocking, sanding, blocking, you get the picture. I must say though that Tom is knocking it out of the park. That's all I have for now. Will try to keep everyone in the loop.